Engineers at Stanford University have created a small, autonomous device with a stretchable and flexible sensor that can be adhered to the skin to measure the changing size of tumors below. The non-invasive, battery-operated device is sensitive to one-hundredth of a millimeter (10 micrometers) and can beam results to a smartphone app wirelessly in real time with the press of a button.

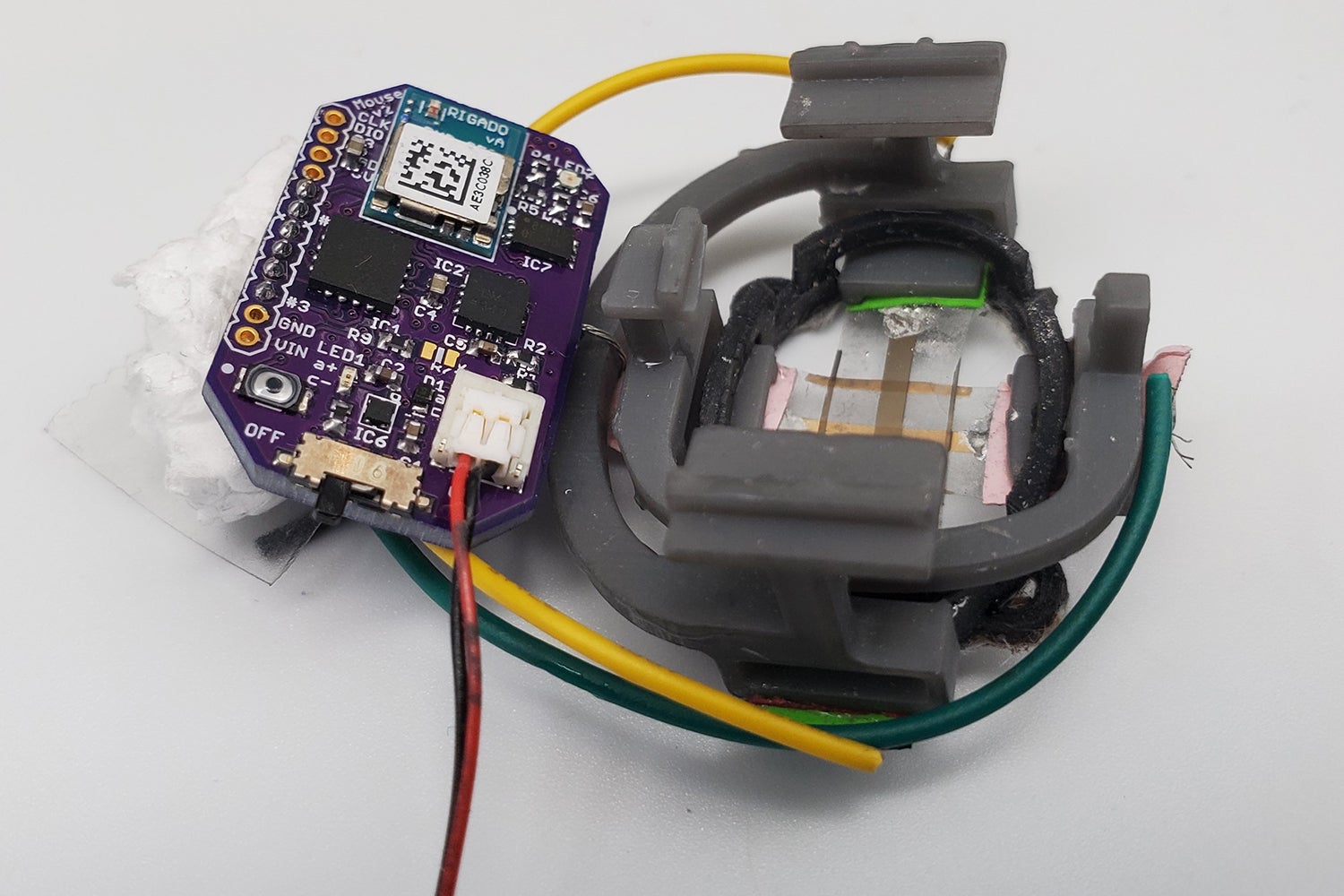

The FAST system measures tumor size regression and is a new way to test the efficacy of cancer drugs. (Image credit: Alex Abramson, Bao Group, Stanford University)

In practical terms, the researchers say, their device – dubbed FAST for “Flexible Autonomous Sensor measuring Tumors” – represents a wholly new, fast, inexpensive, hands-free, and accurate way to test the efficacy of cancer drugs. On a grander scale, it could lead to promising new directions in cancer treatment. FAST is detailed in a paper published Sept. 16 in Science Advances.

Each year researchers test thousands of potential cancer drugs on mice with subcutaneous tumors. Few make it to human patients, and the process for finding new therapies is slow because technologies for measuring tumor regression from drug treatment take weeks to read out a response. The inherent biological variation of tumors, the shortcomings of existing measuring approaches, and the relatively small sample sizes make drug screenings difficult and labor-intensive.

“In some cases, the tumors under observation must be measured by hand with calipers,” says Alex Abramson, first author of the study and a recent postdoc in the lab of Zhenan Bao, the K.K. Lee Professor in Chemical Engineering in the Stanford School of Engineering.

The use of metal pincer-like calipers to measure soft tissues is not ideal, and radiological approaches cannot deliver the sort of continuous data needed for real-time assessment. FAST can detect changes in tumor volume on the minute-timescale, while caliper and bioluminescence measurements often require weeks-long observation periods to read out changes in tumor size.

The power of gold

FAST’s sensor is composed of a flexible and stretchable skin-like polymer that includes an embedded layer of gold circuitry. This sensor is connected to a small electronic backpack designed by former postdocs and co-authors Yasser Khan and Naoji Matsuhisa. The device measures the strain on the membrane – how much it stretches or shrinks – and transmits that data to a smartphone. Using the FAST backpack, potential therapies that are linked to tumor size regression can quickly and confidently be excluded as ineffective or fast-tracked for further study.

Based on studies with mice, the researchers say that the new device offers at least three significant advances. First, it provides continuous monitoring, as the sensor is physically connected to the mouse and remains in place over the entire experimental period. Second, the flexible sensor enshrouds the tumor and is therefore able to measure shape changes that are difficult to discern with other methods. Third, FAST is both autonomous and non-invasive. It is connected to the skin – not unlike an adhesive bandage – battery operated, and connected wirelessly. The mouse is free to move unencumbered by the device or wires, and scientists do not need to actively handle the mice following sensor placement. FAST packs are also reusable, cost just $60 or so to assemble, and can be attached to the mouse in minutes.

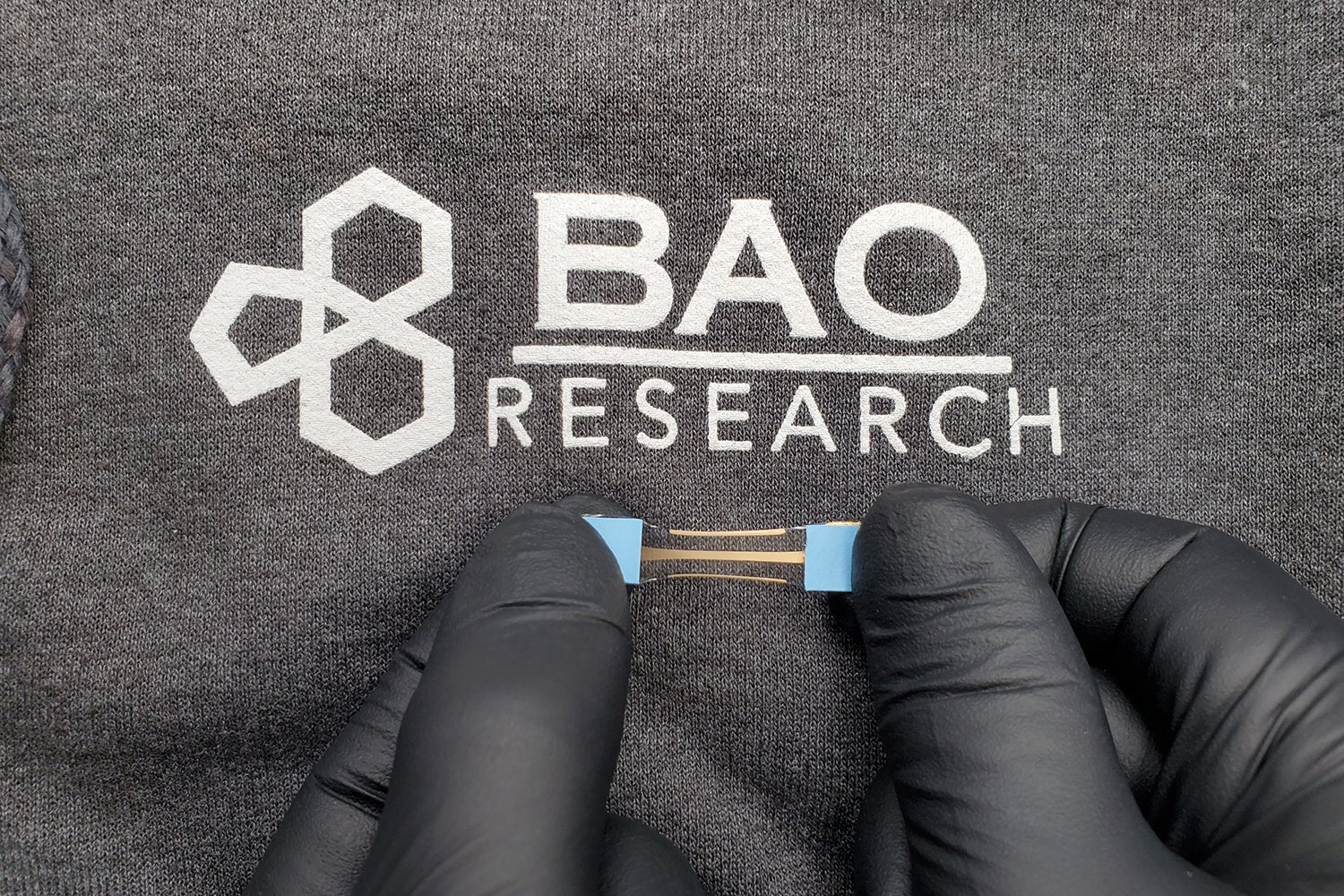

FAST’s sensor is composed of a flexible and stretchable skin-like polymer that includes an embedded layer of gold circuitry. (Image credit: Alex Abramson, Bao Group, Stanford University)

The breakthrough is in FAST’s flexible electronic material. Coated on top of the skinlike polymer is a layer of gold, which, when stretched, develops small cracks that change the electrical conductivity of the material. Stretch the material and number of cracks increases, causing the electronic resistance in the sensor to increase as well. When the material contracts, the cracks come back into contact and conductivity improves.

Both Abramson and co-author Matsuhisa, an associate professor at the University of Tokyo, characterized how these crack propagation and exponential changes in conductivity can be mathematically equated with changes in dimension and volume.

One hurdle the researchers had to overcome was the concern that the sensor itself might compromise measurements by applying undue pressure to the tumor, effectively squeezing it. To circumvent that risk, they carefully matched the mechanical properties of the flexible material to skin itself to make the sensor as pliant and as supple as real skin.

“It is a deceptively simple design,” Abramson says, “but these inherent advantages should be very interesting to the pharmaceutical and oncological communities. FAST could significantly expedite, automate, and lower the cost of the process of screening cancer therapies.”

Alex Abramson is now assistant professor of chemical and biomolecular engineering at Georgia Institute of Technology; Yasser Khan is assistant professor at the Ming Hsieh Department of Electrical and Computer Engineering at the University of Southern California; and Naoji Matsuhisa is associate professor in the Institute of Industrial Science Department of Informatics and Electronics at the University of Tokyo. Additional Stanford co-authors are Carmel T. Chan, former senior scientific manager; undergraduate Alana Mermin-Bunnell; Robyn Fong, life science research professor in the Department of Cardiothoracic Surgery; Rohan Shad, former postdoctoral fellow at the School of Medicine; William Hiesinger, assistant professor of cardiothoracic surgery; and Parag Mallick, associate professor of radiology. Zhenan Bao is also a member of Stanford Bio-X, the Stanford Cardiovascular Institute, and the Wu Tsai Human Performance Alliance. Hiesinger and Mallick are also members of Stanford Bio-X and the Cardiovascular Institute.

The research was supported in part by the National Institutes of Health and the Stanford Wearable Electronics Initiative (eWEAR).

The eWEAR-TCCI awards for science writing is a project commissioned by the Wearable Electronics Initiative (eWEAR) at Stanford University and made possible by funding through eWEAR industrial affiliates program member Shanda Group and the Tianqiao and Chrissy Chen Institute (TCCI®).

Media Contacts

Jill Wu, Stanford University School of Engineering: (386) 383-6061, jillwu@stanford.edu